Continuous Stirred Tank Reactor

CSTR stands for “Continuous Stirred Tank Reactor”. This type of reactor operates continuously and in a steady state. CSTR is commonly just a tank this could be small like a pilot plant or very large for an industrial setting. In this tank, some stirring apparatus moves and agitates the fluid within the reactor to promote better mixing. There could be several inlets feeding the reactor and an outlet to remove the reacted products.

Continuous stirred tank reactor (CSTR) is the most generally employed bioreactor for bio-hydrogen production in continuous mode due to its simplicity in configuration, easy functioning, efficient uniform stirring, and proper maintenance of temperature and pH. It is used commonly for liquid or suspension reactions yet rarely occupied as means for gas-phase reactions.

If we have a heating or cooling jacket over the CSTR the energy is going to be applied to the walls of the reactor. However, since the mixing is so good and the convection of heat quickly reaches a steady state. Therefore, we have an excellent heat transfer occurring. CSTR can be found in industries where less viscous fluids are used and where a steady-state is ideal.

You may also search for: Plug Flow Reactor.

CSTR Ideal Assumptions

CSTR is one of the few ideal reactors. The ideal assumptions of CSTR are;

- Steady-state / Continuous process: Nothing changes in time

- Perfectly mixed: The mixture within the CSTR is so well mixed that the composition, temperature, and other characteristics of the mass anywhere within this reactor will give us the same results.

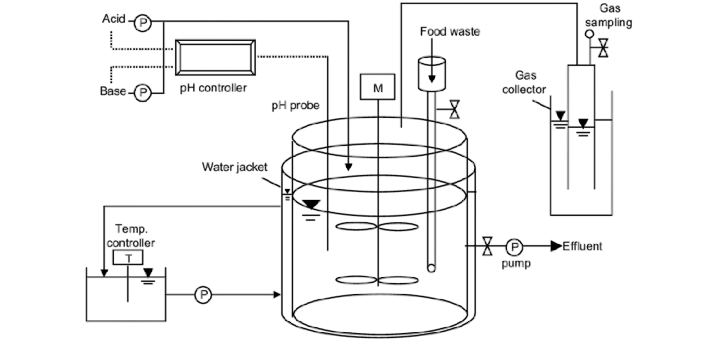

Diagram

In an ideal tank reactor, the entire tank is assumed to be perfectly mixed which means that there is no variation inside and the mixing time is essentially zero.

But in practice, we know that it takes time and there will be variation in the tank. The fluid near the impeller is mixed rapidly but the fluid in the remainder of the tank is much slower to mix. This can result in two problems. The first is the dead zone this is the part of the tank where the mixing is minimal and the mixing time is extremely long. The second problem is of bypassing in CSTRS in which the reactants are continuously added to the tank but some of the reactants bypass the impeller region and leave quickly through the outlet then the residence time of the reactant is much less than the average residence time in the tank because of imperfect mixing there is not a single residence time in a CSTR but the residence time distribution must be developed for the reactor model.

Kinds of phases

The following kinds of phases are present in CSTR are:

- Liquid phase

- Gas-liquid reactions

- liquid-solid reactions

CSTR formula

Let’s create a mole balance for some generic component inside our batch reactor;

Accumulation= Input- Output+ Generation- Consumption

In the CSTR reactor input and output must be equal because of the steady-state condition so the accumulation will be zero in the above equation. So the equation will be;

=

Here, is the generation of component A and is equal to ()

The final equation becomes

=

So we can find the volume of the reactor using this equation. This is called the general design equation for CSTR.

Uses of CSTR

- When agitation is required, CSTR is required because its name is “Continuous Stirred Tank Reactor”.

- When the series configuration for different concentration streams is required.

Advantages of CSTR reactor

- It is in continuous operation.

- It has good temperature control.

- It is easily adaptable for two-phase running.

- Good control.

- Its construction is very simple.

- Its labor cost is low.

- It is easy to clean.

Disadvantages of CSTR reactor

- It has the lowest conversion per unit volume.

- Bypassing and channeling possible with poor agitation.

- In CSTR, the dead zone is developed where no mixing can occur.