Laser beam welding is used for metal vaporization it is not using any other welding process and hence it can be used in other eye surgeries as you can do laser operation by using a laser beam and various processes in which cleanliness is a part. Welding vacuum is not required it is a clean process so you have an advantage on other beams welding.

What is the laser?

A laser is a light amplification for simulation, emission, and radiation. It is a monochromatic light source that directly falls on the object to be welded or on the object where the laser is to be provided. For example, if you want to do a laser eye surgery a laser beam is required with a prescribed prescription. It falls on your eye and the surgery is done. A laser beam excites your atom in the medium so when I talk about laser it is very intense monochromatic and strictly directional it won’t go away from its path.

What happens in laser beam welding?

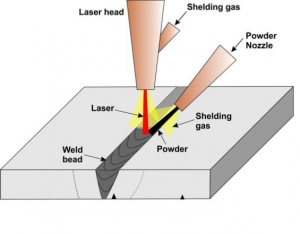

When your laser falls on your object your exact object is welded and heat is generated at the Plated of the place where welding is done. The arrangement of the laser beam welding is a flash tube is used inside that a ruby crystal is placed where you have mirrors. This is a base arrangement of laser beam welding, unlike other welding processes a filler metal is not required in the laser beam.

The basic process of laser beam welding is the electrical energy is converted into light also the voltage is high with a higher energy density. The chromium atoms inside your ruby tubes get excited as rays fall, so welding is done.

Mechanics of laser beam welding:

The basic mechanics of laser beam welding is generating heat, which is just obtained when your ray of light comes and falls on the surface to be welded. The laser beam has the following three steps;

- Interaction of laser beam with the base.

- Heat conduction and rising in temperature.

- Vaporization takes place at the surface to be welded along with vaporization your exact joining takes place.

This is the basic process of laser beam welding.

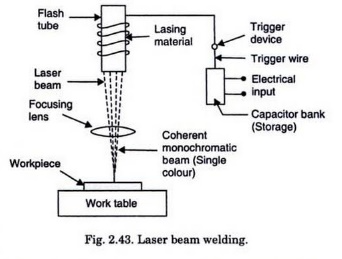

Diagram:

In this diagram we can see that there is an electrical arrangement which provides your laser. There is a mirror inside your tube that is also focusing length is provided and then your laser beam is coherent and it reaches at a single point and that single point beam goes out. So, this is the whole arrangement for making a laser beam and it comes out in the form of a laser which is monochromatic and as well as directional.

Advantages of laser beam welding:

- It can easily dissimilar metals.

- It is directional, if it goes in a single path.

- It can also be used in open air.

- No filler metals are required.

- It has narrow heat affected zone.

- It has low total thermal input.

Disadvantages of laser beam welding:

- Capital cost is high.

- It can build only thinner objects as laser beam cannot pass through thicker objects.

- Maintenance part is a bit high.

- Rapid cooling is major disadvantage of laser beam welding. When rapid cooling is occur the metal which is welded may cracked.

- The optical surfaces of the laser are easily damaged.