PFR stands for a Plug flow reactor. Like CSTRs PFRs also operate continuously, meaning they are a steady-state process.

So if we are operating our plug flow reactor here at a steady state, then one meter into our reactor should always give the same composition in the theory. Because our plug flow reactor is a steady-state reactor, we will continuously feed it reactants and remove products at the same time. The idea here is that new reactants enter our tank, stay reacting for a certain amount of time called the residence time, and then leave the reactor once the reactant has become the product.

How residence time of PFR is different from CSTR:

The plug flow reactor’s residence time is slightly different from the CSTRs residence time. In a CSTR the residence time is a distribution based on statistics and that is why it looks like a bell curve, it is based on the average time a particle spends in the CSTR. Whereas in a plug flow reactor we have just a single residence time as we are assuming that the fluid is continually and always moving forward at a constant rate.

What Plug Flow Reactor looks like:

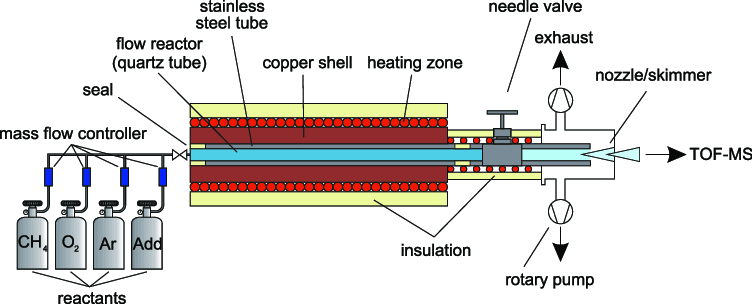

PFR is commonly a long coiling tube in which there is a reacting component. Commonly we will also have a heating or cooling jacket around the reactor. This is to manage the temperature of the system. These two jackets are used will depend on the reaction occurring and whether it is exothermic or endothermic.

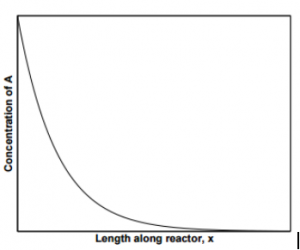

In these types of reactor, there is just one inlet and one outlet and as the reactants work their way through the reactor it is constantly being converted to the product of interest. As we can imagine this plug shape here acts as an infinitely small CSTRs and by stringing our infinite amount of CSTRs together we get a plug flow reactor.

In terms of industrial use, these types of reactors are commonly found in the petrochemical, pharmaceutical, and several other chemical-based industries.

PFR Ideal Assumptions:

- First we assume that there is no axial mixing in the reactor.

- We assume perfect radial mixing.

Perfect radial mixing means that if we were to take a cross-section at any point in our ideal plug flow reactor, we would have the exact composition and temperature throughout that entire cross-section.

Therefore, because of these two assumptions and how to plug flow reactor, we track the changes in our fluids composition as a function of distance through the plug flow reactor rather than the time like we did with our other reactors like batch and CSTR.

PFR Formula:

General mole balance:

Accumulation = Input- Output+ Generation

As we mentioned above it is in steady-state and input is equal to output so in case;

*Accumulation = 0

Then equation becomes;

Here,

We make this control volume infinitely small because we are studying here plug flow reactor and we get the following;

As our 0, dV

Uses of PFRs:

Some uses of PFR are following;

- PFR is used for large-scale production.

- It is used in high temperatures.

- PFR is used for fast reactions.

- It is used in both homogeneous and heterogeneous reactions.

- It is used for continuous production.

Advantages of PFRs:

- They are great for gas phase and liquid phase reactions.

- Fast reaction times in plug flow reactors and therefore we have a higher level of conversions for volume needed.

- Easily saleable.

Operating continuously is great for the industrial scale-up of reactors vs things like batch and semi-batch which are harder to scale up.

- We can also achieve higher temperatures in PFRs which are sometimes necessary for some reactions.

- We have lower labor costs as the reactor will mostly be running itself as it is in a steady-state.

Disadvantages of PFRs:

- PFR has poor temperature control.

- Hot spots may occur when used for an exothermic reaction

- It has undesired thermal gradients that may exist.

- Channeling may occur in PFR.

- Unit of PBR may be difficult to service and clean.

- Shutdown and cleaning of PFR may be expensive.