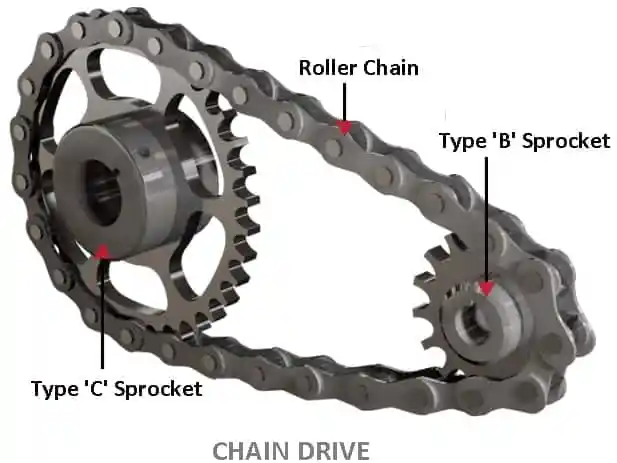

Chain drive

A chain drives is a mechanically operating system where we use different types of chains to transmit the power between sprockets. A chain drive consists of a chain and two wheels called sprockets. A chain can be defined as a series of links connected by pin joints. The sprockets are toothed wheels over which an endless chain is fitted.

Generally, a chain drive is used where the distance between the power produced is less. However, in some cases, we can use a chain drive for longer distances of power transmission. In belt or rope drive we see there is some percent of slip occurs but in the chain there will be no slip but some amount of power loss we can generally see. drives chains are employed for a wide range of power transmissions like in bicycles, motorcycles, rolling mills, agriculture machinery etc.

Types of chains drive

Chain drives can be classified into three broad categories and those are;

- Hosting and hauling chains

- Conveyor chains

- Power transmission chains

Hosting chains:

A hoist is a device that is used to lift a load or lower a load. It can be used for shifting some heavy products from one place to another place in a workstation. The chains used in this type of device is named hoist chain. These chains are quite strong to handle heavy weight. it can be operated manually, electrically, or pneumatically the best-known elevator. The carriage is raised and lowered by a lifting mechanism. Most hoists are attached to their loads with a lifting hook. Hoist chains can be classified into two types;

Oval link chains:

Oval links chains consist of many over-links attached to each other links of this type of chain are oval. However, there are square link types of chains that are also available but the kinking has occurred easily due to high loading. Generally, these types of chains are used at low speeds only.

Stud link chains:

The stud link chains used to minimize the deformation and link easily. In this type of chain, a round bar or stud is used to fit inside the oval link chains to provide them more strength. It is used in ship to up and down the anchor of the ships and same crane hoist where we need to lift a very high amount of load.

Conveyor chains:

A conveyor chain is a chain that has been specially developed for chain conveyor systems. It consists of a series of plane bearing that are held together by connecting plates. Each bearing consists of a pin and bushing on which the chain roller rotates. It is used to move materials from one place to another. This type of chain is well shaped that it can easily run over the sprocket. The one major advantage of this type of chain is the motion of the chain is not smooth and also there are chances of wear and tear. There are two types of conveyor chains which are given below;

-

Detachable or hook joint chain:

This type of conveyor chain is used in a conveyor where the length between power transmissions is short.

-

Closed joint type chain:

This type of chain consists of a barrel and link and is made into a single casting.

Power transmission chains:

Power transmission chains are used for the transmission of mechanical power when the distance between shafts is short. These chains have provisions for efficient lubrication. This type of chain has greater accuracy and can easily run over the sprocket. The power transmission is of the following types;

-

Block or bush chain:

This type of chain was used in the initial stage of development in power transmission. It causes noise when rubbing the teeth and the link when the sprocket is near or exiting the teeth. these types of chains are used to some extent at small speeds as conveyor chains

-

Roller chain:

In this type of chain, a bush along with the roller is fitted inside both the plates then a pin is passed through both ends of the roller to fasten it the roller is free to rotate inside the bush. So, when it contacts between the sprocket the wear and tear of the chain would be reduced. It is soundless as compared to the block-chains and these chains gave much service area if proper lubrication is maintained. It is used in high-power transmission devices like a motorcycle.

-

Silent or invented toothed chain:

The operation of this type of chain is quite silent and can be used in high-speed power transmission areas. These chains do not have any roller. It is accurately shaped so that it can easily sit over the sprocket. However, lubrication is an important factor for this type of chain. Otherwise, it will wear and tear.

-

Leaf chain:

Leaf chains are designed for lifting rather than power transmission. Tensions are very high but speeds are slow normally the chains work intermittently. A leaf chain is the most simple of steel chains consisting only of link plates and pins. This chain has generally tensile strength than roller chains and runs over sheaves rather than sprockets. They are suitable for hanging balancing or motion transmitting applications.

-

Flat top chains:

Flat top chains are widely used on conveyors most basically used on the special type of slack conveyor. The flat top chain consists of a series of steel top plates with hinge-like barrels curled on each side. Pins are inserted through barrels to make a joint the flat top chain is intended only for conveying. These chains are available for straight or curved tracks and with the various joint types plate thickness and materials whether they are made from steel, stainless steel, or plastic. These chains are high wear resistance and high-quality workman ship. Although they are mainly used in the beverage industry and also can be found in many other industrial applications.

-

Engineering steel chain:

Engineering steel chains were first developed in the 1880s were designed for difficult conveying applications. Most engineering steel chains are sued in conveyors bucket elevators and tension linkages only a few are used in drives. The main design considerations for these chains are tensile loads. Several types of wear lubrication and the environment.

-

Chain drives used in bicycles:

Most bicycle chains are made from plain carbon or alloy steel but some are nickel plated to prevent rust or simply for style. Chain drive was the main feature that modified the safety bicycle introduces in 1885 with its two equal-sized wheels from the high wheeler type of bicycle. The popularity of chain-driven safety is still a basic feature of bicycle design today. A bicycle chain has very high efficiency because it moves from the point of pressure farther away from the axle putting less stress on the bearings as a result of reducing friction in the inner wheel. The higher chain tension was found to be more efficient.

-

Chain drives used in automobiles:

A chain drive system transmits power from a differential to the rear axle in a vehicle. Back in earlier days, automobile chain drives are a very popular power transmission system. It gained prominence as an alternative to the system pan with its rigid Hodgkin’s drive shaft and universal joints. Drives chains are simpler to design than driveshaft and universal joints because of less un sprung weight. At the rear wheels it allows the suspension to react to bumps more effectively by this means the vehicle would have a smoother ride.

-

Chain drives used in motorcycles:

In most of the motor cycles chain drive is used to transmit power to the rear wheels. This drive chain requires two sprockets one on the output shaft of the transmission and the other on the wheel just like a cycle. The sprocket size differs depending upon the engine’s power and torque output. This is the drive system that an overwhelming majority of motorcycles implement.

Chain and sprockets are the most efficient at transmitting power with only one to four percent transmission loss that’s significantly less than bell drives. Chain drives are very simple in their functioning and are very cost effective to run and replace too. Chain drive versus belt drive or use of a drive shaft is a fundamental design decision in motorcycle design. Nearly all motorcycles use one of these three design.

Advantages of chain drive:

- They can be used for both long and short distances.

- A number of shafts can be driven from a single chain.

- They are compact and have small overall dimensions.

- They do not present fire hazard.

- They do not require initial tension.

- They have very high efficiency.

- They do not slip.

- Easier to install.

- Withstand abrasive conditions.

- Operate in wet conditions.

Disadvantages of chain drive:

- It requires frequent lubrication to avoid rust.

- It cannot be used where there is a requirement of slips.

- We can’t keep chain drive and open it. Need housing or covering.

- The initial or installation cost is more.