The reactants are added to the reactor in which the reactants are reacted for a fixed time. There is no feed added and the product is drawn within this time. The reaction products are removed at the end of the reactor.

The batch reactor is considered one of the ideal reactors in all types of reactors. We assume the constant volume and the system are well mixed for the batch reactor. Ideal reactors make the calculation easier and serve as a learning step for more complex and efficient reactors.

How it works:

So the way of batch reactor operates is by first adding in all reactants, catalysts, and whatever is needed for the reaction. We then close off the reactor and let it react for a certain amount of time and the tank could be heated. We would say let our components react for 5 hours at 50-degree Celsius. After 5 hours we would remove the reacted products.

These reactors are very common at a small scale and for batch-sensitive materials. These types of reactors are often slow, expensive, and labor-intensive compared to some other methods but it works very well for certain applications. It is very common to see these types of reactors in the pharmaceutical, food industry, and many others.

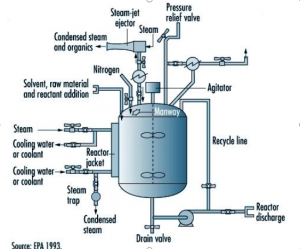

Diagram:

This is the diagram of the batch reactor which is the simplest reactor used in the chemical industry. The reactants are placed in the reactor and then allow to react and products form inside the reactor. The products and unreacted reactants are then removed and the process is repeated. The batch reactor contains ports for injecting reactants and removing products and can be outfitted with the heat exchanger or a stirring system. These are generally of constant volume and some are designed to maintain the constant pressure by varying the reactor volume.

Types of batch reactors:

- Non-Isothermal: This is the system in which the temperature changes.

- Isothermal: This is the system in which the temperature is constant.

- Adiabatic: This is the system where no heat is transferred to the environment. The reason this depends on the reaction occurring within it is that we do not want an adiabatic system for a highly exothermic reaction since we are likely going to need a cooling agent to keep the temperature down.

Kinds of phases:

Three kinds of phases are present in the batch reactor which are following:

- Gas phase

- Liquid phase

- Solid-liquid phase

The mathematical equation for batch reactor:

Let’s create a mole balance for some generic component inside our batch reactor;

Accumulation= Input- Output+ Generation- Consumption

Since we add all out components before time zero, there is no flow into the reactor. Additionally, there is no flow out of the reactor either, and therefore, both terms of input and output become zero, and accumulation is equal to generation.

Accumulation= Generation- Consumption=

*(= .V)

Here,

.V= rate of formation or consumption of components “a”

Example:

Let’s consider the isomerization of species A in a batch reactor

A→B

As the reaction proceeds, the number of moles of A decreases, and the number of moles of B increases. We might ask what time, is necessary to reduce the initial number of moles from to a final desired number . Applying the above equation to the isomerization.

Rearranging,

=

and integrating with the limits that at t=0, then = , and at t= , then , we obtain

This equation is the integral form of the mole balance on a batch reactor. It gives the time necessary to reduce the number of moles from and also to form moles of B.

Batch reactor uses:

A batch reactor is a vessel equipped with an agitator and is used for

- Dissolution of solid with solvent

- Hydrogenation

- Chemical Reactions

- Batch Distillation

- Crystallization

- Fermentation

- Liquid-Liquid Extraction

- Pharmaceutical

- Production of pulp

- Heating

- Cooling

- Small scale Production

- Intermediate Production

Advantages of batch reactor:

- The major advantage of the batch reactor is of high conversion per unit volume for one pass that may be obtained by leaving the reactant within the reactor for a long period.

- It is easy to clean.

- It has no hindrance

- It is cheap and applicable to developing countries.

- In batch reactors the same reactor can produce one product one time and a different product the next.

- It is versatile, used to make many products.

- High flexibility in operating conditions.

Disadvantages of batch reactor:

- It has a high cost of labor per unit production.

- It is difficult to maintain large-scale production.

- It has long idle time means charging and discharging time so in results of no production.

- No instruments have been used in it.

- It has poor product quality.

- Risk explosion during emptying reactors.

- Preferred for a homogeneous reaction only.