-

Fuel Injection system:

The car’s engine requires the correct amount of air and fuel mixture at the right time to run efficiently and smoothly. This was ensured by carburetors in older engines but today those carburetors are replaced by a more efficient and effective system known as the fuel injection system.

Air to fuel ratio:

The ideal air-fuel ratio for combustion in a gasoline engine is typically around 14.7 to 1, meaning 14.7 parts of air are required for each amount of fuel. This is known as perfectly balanced stoichiometric air-fuel ratio which is the ratio that provides complete combustion of the fuel with no excess oxygen and unburned fuel.

Any mixture greater than 14.7 to 1 is considered lean; when it is less than 14.7 to 1, it is known as a rich mixture. The air-fuel ratio is controlled by many factors that are pre-programmed into the engine control unit ECU using a variety of sensors and actuators.

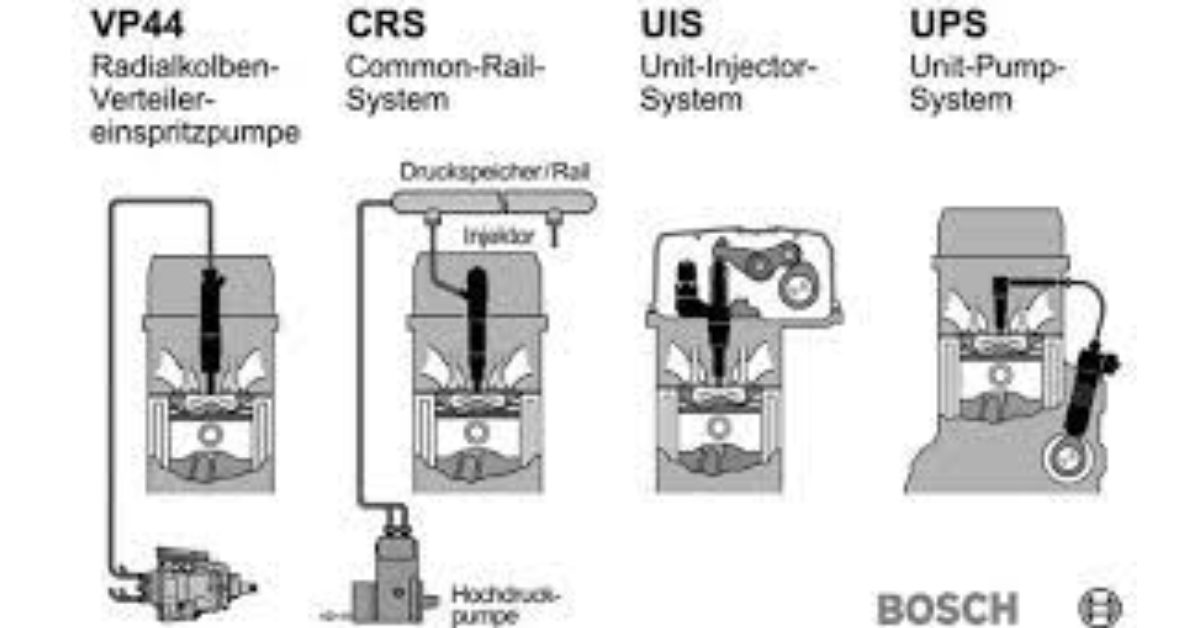

The types of fuel injection systems are given below;

-

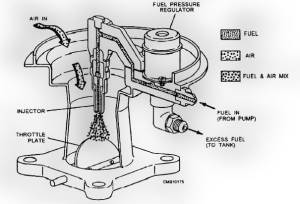

Throttle body injection system:

The throttle body injection system is also known as a single-point injection because it uses a single injector located in the throttle body to deliver fuel to all cylinders. In a single injection, the fuel is injected into the throttle body and then mixed with air as it passes through the intake manifolds and into the cylinders.

Throttle Body Injection System Diagram:

Replaced with carburetors:

It was commonly used in older vehicles and is now less common due to its limited precision and efficiency. At that time throttle body injection was developed as a replacement for carburetors. This system uses a single injector in the throttle body to deliver fuel to the engine, providing better fuel metering and control than a carburetor.

The basic function of the throttle body injection and a carburetor is similar to mixing fuel and air before delivering it to the engine. The throttle body injection is more precise and efficient as air enters the throttle body it passes over the fuel injector. The ECU calculates the precise amount of fuel needed based on inputs. Even though the engine has four cylinders the number of injectors remains one. However, it only uses one injector the engine’s performance at high RPM is also slightly distributed.

-

Port/ Multipoint Injection:

The port or multi-point fuel injection is also known as an indirect injection system. In the Port injection system, the fuel is injected into the intake port rather than directly into the engine cylinder. Each cylinder has a fuel injector located in the engine’s intake port, which sprays fuel into the intake manifolds just before the intake valve opens. The fuel mixes with the incoming air and is drawn into the cylinder when the intake valve opens. The word multi-point fuel injection means the fuel is injected into the intake port of each cylinder individually through a separate injector.

Each cylinder has its fuel injector which means that a four-cylinder engine uses four injectors that are mounted on the intake manifold near the intake port. It is less precise than direct injection but can still provide good fuel efficiency and engine performance. Shooting the fuel vapor this close to the intake port almost ensures that it will be drawn completely into the cylinder.

Advantage:

The main advantage is that multi-point fuel injection meter fuel more precisely than throttle body injection designs better achieving the desired fuel ratio when improving all related aspects.

Development:

In the early 1900s, BOSCH and KLESI CUMMINS decided to improve Rudolph Diesel’s original air-blasted system by introducing a new fuel injection system. This involved injecting fuel directly into the intake port where it mixed with the incoming air from there the spark plugs ignite the pressurized slurry of air and fuel pushing the cylinder head down and spinning the crankshaft. This process occurs simultaneously in each cylinder of the engine.

Example:

In a V6 engine with port injection. The cycle happens so rapidly that it is barely noticeable except for the sound it produces.

Types:

There are three types of multi-point fuel injection systems available. They are;

- Sequential Fuel Injection

- Batched Fuel Injection

- Simultaneous Fuel Injection

Sequential Fuel Injection:

Sequential fuel injection is also called sequential port fuel injection or timed injection. This system is designed to inject fuel into each cylinder in a specific order. The sequential fuel injection system is the same as multi-point fuel injection but this type already has individual injection.

In other words, each injector does not work together but works individually according to the steps of each piston. For example, in a four-cylinder engine when cylinder one is in the suction step only injector one works while the other injectors are idle. The injector is controlled by the engine control unit which ensures that each cylinder receives the correct amount of fuel at the precise moment it is needed.

Sequential fuel injection triggers each injector nozzle independently time like spark plugs they spray the fuel immediately before or as their intake valve opens. Sequential systems are the most precise and efficient type of multi-point fuel injection system.

Batched Fuel Injection:

In the batched system fuel is injected into the groups or batches of the cylinders without bringing their intake stroke together. The fuel is delivered to sets of cylinders at the same time rather than to each cylinder during its specific intake stroke.

In a typical four-cylinder engine with a batched system, the injectors may be divided into two groups each supplying fuel to two cylinders. The engine control unit activates one group of injectors to deliver fuel to cylinders 1 and 4 while the other group delivers fuel to cylinders 2 and 3. The injection timing and duration are controlled by the engine control unit to ensure that each cylinder receives the correct amount of fuel at the right time.

Comparison with sequential fuel injection system:

This system is simpler and less expensive than sequential systems but they may not provide the same level of precision and efficiency because the fuel is delivered in batches there may be slight variations in the amount of fuel delivered to each cylinder which can affect engine performance and emissions.

Simultaneous Fuel Injection:

In the simultaneous system, fuel is injected into all cylinders at the same time. It uses an individual fuel injector for each cylinder thus there is no gas wastage over time. It reduces fuel consumption and makes the vehicle more efficient and economical.

The vehicles with this technology have lower carbon emissions than a few decades-old vehicles. The more precise fuel delivery cleans the exhaust and produces less toxic byproducts. Therefore, the engine and the air remain cleaner. The multi-point fuel injection system enhances engine performance by atomizing the air in a small tube instead of relying on the additional air intake.

-

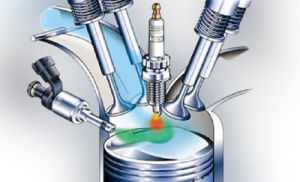

Direct Injection system:

In a direct injection system, fuel is injected directly into the combustion chamber of each engine cylinder rather than into the intake valve so that it looks like a diesel engine where the injector will spray fuel directly into the cylinder. Typically, fuel is injected during the compression stroke of the engine. This allows for better control over fuel and air mixture and can result in improved engine efficiency and performance.

This is the latest type of fuel injection system. In early, direct injection was applied to diesel engines. But now the direct injection system can be used for the gasoline engine but still, the fuel only comes out during the suction step. For gasoline engines, this system is known as gasoline direct injection or GDI.

Working principle:

The high-pressure pump increases the fuel pressure to 500 to 2000 psi. Once the fuel is pressurized it is sprayed through a small nozzle directly into the combustion chamber during the engine’s compression stroke. The fuel is sprayed in a fine Mist that is highly atomized to mix more completely with the air. The fuel mixes with air in the combustion chamber creating a highly combustible mixture that can be ignited by the spark plug. When the spark plug ignites the air-fuel mixture it creates a controlled explosion that pushes the piston down and turns the crankshaft generating power to move the vehicle.

Advantages:

- By injecting fuel into the combustion chamber direct injection systems can provide more precise control over the fuel-air mixture resulting in improved fuel efficiency and engine performance.

- They can also reduce emissions more effectively by burning the fuel

Disadvantages:

- Direct injection systems can be more complex and expensive than other types of fuel injection systems.

- They require high pressures and more precise control over the fuel delivery system.

Types:

It can be classified into three types which are;

- Spray Guided

- Wall guided

- Air guided

Spray Guided:

In the spray-guided direct injection system, the fuel injector is typically located at the top of the combustion chamber next to the spark plug. The fuel is sprayed directly into the combustion chamber in a way that creates a specific pattern or spray shape.

This is done to ensure that the fuel is distributed evenly throughout the chamber and that it reaches all parts of the chamber before ignition. This is designed to maximize fuel atomization and mixing with the air in the combustion chamber. However, it requires careful design of the combustion chamber and fuel injector to optimize the fuel spray pattern and avoid undesirable combustion characteristics such as knock or incomplete combustion.

Wall-guided:

In wall-guided direct injection, the fuel is injected into the combustion chamber in such a way that it strikes the wall of the chamber before being mixed with air. The distance between the spark plug and the injection nozzle is relatively high.

In order to get the fuel close to the spark plug, it is sprayed against a swirl cavity on top of the piston which guides the fuel towards the spark plug. This method of injection typically required a higher injection pressure than the spray-guided method.

In an engine with wall-guided injection special swirl or tumble air intake ports aid this process. The injection timing depends upon the piston speed therefore at higher piston speeds the injection and ignition timing need to be advanced very precisely.

At low engine temperatures some parts of the fuel on the relatively cold piston cool down so much that they cannot combust properly. When switching from low engine load to medium engine load some parts of the fuel can end up getting injected behind the swirl cavity also resulting in complete combustion. Engines with wall-guided direct injection can therefore suffer from high hydrocarbon emissions

Air Guided:

In engines with air-guided injection, the distance between the spark plug and injection nozzle is relatively high. The air intake is used to guide and direct the fuel spray into the combustion chamber. The shape of the combustion chamber is typically designed with a small centrally located injector that sprays fuel directly into the cylinder. The air entering the cylinder is directed by the shape of the chamber creating a Vortex that helps to mix the fuel and air together. The design of air-guided injection systems is more complex and expensive compared to other types of injection systems which may limit their adoption.

-

Dual injection system:

Dual injection systems use two different methods of injecting fuel into the engine direct injection and port injection. It is commonly found in modern gasoline engines and is designed to improve engine efficiency.

In a dual injection system, there are typically two types of injectors a high-pressure direct injector and a low-pressure port injector. The direct injector injects fuel directly into the combustion chamber. While the port injector injects fuel into the intake port of the engine.

At low RPM the system will rely mainly just on the port fuel injector that provides the better air-fuel mixture. This means that the engine will gain all the port fuel injection advantages. However, as the RPM increases the direct injector steps in, and the port injector stops. This increases the combustion efficiency since the direct injection system is faster at higher RPM and could perform better.

When the RPM increases more and more and the direct injector is not capable of providing enough fuel at such high speed the port injector will be there to help. Both injectors will be working together at high RPM to supply the cylinder with the needed amount of fuel.

Advantages:

- Direct injection engines are pros to carbon deposits on the intake valves because fuel doesn’t wash over them.

- In Port injection engines on the other hand injects fuel into the intake manifold following the fuel to wash over the intake valves. While this can help prevent carbon buildup on the back of the valves.

- By combining both systems the dual injection system can reduce the formation of carbon deposits by using the port injectors to wash the intake valves

- Direct injection can lead to engine knock or detonation because of the higher compression ratios and cylinder pressures.

- Port injection can reduce the likelihood of knock because the fuel is introduced before the air enters the cylinder.

- The dual injection system can reduce the risk of engine knock while still providing the benefits of direct injection.

Disadvantages:

- Direct injection can improve fuel efficiency by delivering fuel directly to the combustion but it can also lead to incomplete combustion and higher emissions.

- Port injection can help to ensure that the fuel is fully mixed with the air but it can also reduce fuel efficiency.

- The main disadvantage is that the increased number of moving parts and the increased production costs.