Introduction to engine valve train design:

The valve train is a mechanical system in an internal combustion engine that manages the opening and closing of the intake and exhaust valves. Its purpose is to regulate the timing of these valve operations to allow the intake of the air-fuel mixture into the combustion chamber and the explosion of exhaust gases.

During the intake stroke, the intake valves control the air-fuel mixture’s flow into the combustion chamber. During the exhaust stroke, the valves regulate the flow of spent exhaust gases out of the combustion chamber. The valve trains to ensure efficient combustion and optimal engine performance by coordinating the timing of valve openings and closings.

Advanced technologies like variable valve timing and variable valve lift allow for even greater control over valve operation. Optimizing performance across various operating conditions.

Parts of engine valve train:

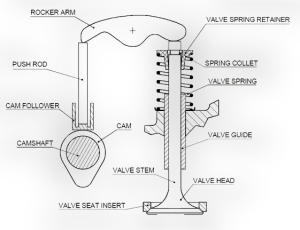

The valve train consists of various components that work together to control valve operation;

- Camshaft valve

- Valve spring

- Lifters

- Pushrod

- Rocker’s arm

- Timing Mechanism

Types of valve train:

- Overhead valve

- Overhead camshaft

- Dual overhead camshaft

Overhead valve engine: (OHV)

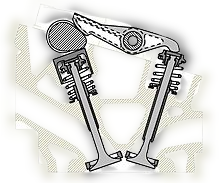

An overhead engine also known as a push rod engine or an I-head engine is a type of internal combustion engine design commonly used in a wide range of vehicles. In this engine, the valves are located in the engine block but the valve mechanism is operated by push rods and rocker arms positioned in the cylinder head above the combustion chamber. This configuration allows for a more compact cylinder head design compared to engines with valves located directly in the head.

Advantages:

Overhead valve engines offer several advantages;

- The use of push rods and rocker’s arms allows for a more compact cylinder head design making the engine lighter and more compact overall.

- Overhead valve engines are generally less expensive to produce compared to overhead camshaft engines as they have a simpler valve train system.

- Overhead valve engines are known for their high torque output, particularly at lower RPMs. this makes them well-suited for applications that require low-end power such as Towing and off-roading.

Disadvantages:

However, these engines have some limitations the push rod and rocker’s arm mechanism may limit the engines’ maximum capability.

- The design of the valve train in the overhead valve engine may limit the engine’s breathing efficiency which can impact its overall performance. This means a small overhead valve engine will not be very efficient.

- This design is more suitable for larger V6 and V8 engines. You won’t find this engine in a modern compact car.

Examples:

CHRYSLER HEMI V8 and GML SA V8 are examples of overhead valve engines.

Overhead Camshaft: (OHC)

An overhead camshaft engine is a type of internal combustion engine in which the camshaft is responsible for operating the engine’s valves that are positioned within the cylinder head above the combustion chamber.

In an overhead camshaft engine, the camshaft is driven by the crankshaft through the timing belt, timing chain, or gears. Single overhead camshafts and dual overhead camshafts are variations of overhead camshaft engines. They refer to the number of camshafts present in the engine design. In a single overhead camshaft engine, there is one camshaft per bank of cylinders. This single camshaft is responsible for operating both the intake and exhaust valves in the engine.

Therefore, a straight has a total of one camshaft, and a V engine or flat engine has a total of two camshafts, one for each cylinder bank. These are commonly found in a variety of vehicles and they are widely used in mainstream automotive applications and can provide a good balance between performance, efficiency, and cost-effectiveness.

Advantages:

- It is a simpler and lighter version of the more complex dual overhead cam setup.

- The single overhead cam setup involves fewer moving parts hence it’s easy to repair.

- It is less expensive to maintain and manufacture.

- The benefit of the overhead cam setup is that it allows for more intake and exhaust valves meaning fuel-air and exhaust can move more freely through the engine adding power.

- More power, more fuel consumption. Thus when talking in terms of single overhead cam versus dual overhead cam fuel efficiency, a single overhead cam is more fuel efficient.

Disadvantages:

- In single overhead camshaft is usually placed in the middle of the head which denies the spark plug in its ideal location.

- These designs have less control over valve timing as compared to dual overhead cam.

- It is simply a single camshaft regulating both the inlet and the outlet of gases. Thus, this engine will gain heat faster than a dual overhead cam.

Dual overhead Camshaft: (DOHC)

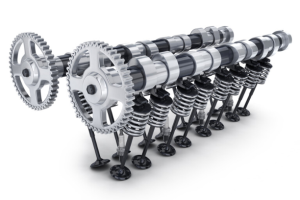

Dual overhead camshaft engines are also referred to as twin-cam engines. There are two camshafts per bank of cylinders. One camshaft is dedicated to operating the intake valves while the other camshaft is responsible for the exhaust valves

In a straight engine, there are two camshafts one for intake and one for exhaust valve. In a V engine or flat engine where the cylinders are arranged in a V-shape or horizontally opposed you would have four camshafts. Each cylinder bank would have two camshafts one for the intake valves and one for the exhaust valves.

History:

The first production car to feature a dual camshaft engine was built in 1910 highlighting the early adoption of this configuration. From the 1940s onward the use of these engines gradually increased leading to their widespread adoption and many automobiles by the early 2000s.

One of the earliest examples was the 1906 Grand Prix-winning Flat S76 also known as the beast of Turin. This vehicle featured a massive 28.5 liter inline 4-engine with dual overhead camshafts.

PUJO’S early double overhead camshaft engine proved quicker than anything else on the track. Armed with the new dual overhead technology. It won the 1912 French Grand Prix. In 1913, Peugeot used its dual-cam engine to become the first foreign automaker ever to win the Indianapolis Grand Prix.

Advantages:

- By having 4 valves in a cylinder instead of two a larger portion of the area can be used to let the air in and exhaust out.

- The engine can make more power if more air enters the cylinder and it wastes less power if it is easier to pump the exhaust out of the cylinder.

- At higher engine speed, the engine pumps a lot of air through the cylinders.

- Having 4 valves per cylinder allows the engine to pump enough air to run and make useful power at these higher speeds.

- Most dual overhead cam engines with two camshafts one per cylinder bank are still capable of providing improved valve control, Higher RPM capabilities, and enhance performance compared to single overhead cam engines.

- The dual camshafts allow for more precise control over valve timing and lift contributing to better engine breathing and power output.

Flathead engine:

Flathead also known as a side valve engine or valve in a block in an engine refers to a type of internal combustion engine design where the combustion chamber and valve are located within the engine block resulting in a relatively flat cylinder head. The valves are positioned beside the piston in the cylinder rather than in the cylinder head.

Flathead engines were widely used in early automotive applications, especially in the early to mid of 20th century. However, they have been largely replaced by overhead valve and overhead cam designs in modern vehicles due to their limitations. It’s worth noting that some enthusiasts still appreciated flat-head engines for their simplicity vintage appeal and nostalgic charm. Additionally, certain industries such as marine and small engine applications still utilize flathead designs for their specific requirements.

Flathead engines were known for their simplicity and low manufacturing cost. However, they did have certain limitations in terms of combustion efficiency and performance. Flathead engines feature a valve gear system that includes a camshaft located in the cylinder block. This camshaft operates the poppet valves through tappets and short push rods.

Flathead design eliminates the need for additional valve train components such as lengthy push rods rocker arms overhead valves or overhead camshafts. In a typical flathead engine, the side valve is positioned adjacent to each other on one side of the cylinder. However, there are also flathead engines that utilize the less common cross-flow or T-head configuration. In the T-head engine, the exhaust gases exit on the opposite side of the cylinder from the intake valve. The combustion chamber in a side valve engine is located to the side of the piston above the valves. The position of the spark plug can vary being located either above the piston or above the valves.

Flathead engines may utilize pop-up pistons to increase the compression ratio and optimize the combustion chamber shape to prevent knocking.

Disadvantages:

One of the limitations of flathead engines was the valve design.

- The intake and exhaust valves were located in the engine block alongside the combustion chamber and they were positioned horizontally.

- This design restricted the airflow into and out of the combustion chamber leading to less efficient combustion and reduced power output.

- Additionally, the flathead design limited the compression ratios that could be achieved.

- The flat shape of the combustion chamber and the position of the valves made it challenging to create a compact and efficient combustion chamber design. As a result, flathead engines typically had lower compression ratios which affected their overall performance and efficiency.

Advantages:

Despite these limitations, flathead engines were widely used during the time due to their;

- Simplicity

- Affordability

- Reliability

However, as automotive technology advanced other engine designs with improved airflow and higher compression ratios emerged eventually leading to the decline in the use of flathead engines and modern vehicles.

Cars with flathead engines:

Flathead engines are widely used in various automobile including notable models such as FORD model T, FORD model A, FORD flathead V8 engine and the FORD side valve engine. Cadillac also produced V16 flathead engines for their luxury cars during a specific period.

The FORD model T which was introduced in 1908 utilized a four-cylinder flat head engine. It played a significant role in popularizing flathead engines and making automobiles more accessible to the masses.

The FORD flathead V8 introduced in 1932 was a groundbreaking development. It featured eight cylinders in AV configuration and became influential in the hot rod and custom car scene.

After the World War 2, flat head designs gradually gave way to overhead valve designs that offered advantages such as improved performance higher RPM capabilities and better breathing efficiency. Today flathead engines are no longer commonly used in mainstream automobiles. They still hold historical and cultural significance. Restored flathead engines can be found in vintage and classic car collections particularly in the realm of custom cars and Hot rods where enthusiasts appreciated their iconic design and nostalgic appeal.

Several notable motorcycle manufactures such as Harley-Davidson employed flathead V-twin engines in their models in early 1900s. these engines played a crucial role in establishing Harley-Davidson’s reputation and contributed to the development of the American Motorcycle industry.

Indian another renowned American motorcycle manufacturer also utilized flathead V twin engines in their motorcycles during the pre-war era. These engines powered many Indian models and contributed to the company’s success.

Triumph and BSA also featured flathead engines in their early models. The utilization of flathead engines in early motorcycles contributed to the development of the motorcycle industry and played a significant role in the evolution of motorcycle technology. These engines are still celebrated today for their historical significance and are often seen in vintage motorcycle restorations and collection.

You can also read this Types of Fuel Injection Systems.